I quickly learned that I had forgotten everything I remembered about the saltwater hobby. I read so much and tried to piece together what I would need to get, but it took time and a few mistakes. So I am going to try and capture how I set my tank up in the hopes that other's who may want to get into the hobby can learn from my mistakes and learn what worked as well.

1. A TANK AND STAND

I was taking my time on finding a tank. Eventually I found a tank that had never even been used on Craigslist along with a stand. The tank is a 125 gallon tank (72" x 18" x 24") and the guy I bought it from gave me the stand he had built.

2. SUMP

This tank already had 2 pre-drill holes and two overflow boxes in each corner. Every tank can be different in how water will drain so I was lucky in that mine was already set up. Once you figure out how your drains will be set up, the next thing to figure out is what your sump will look like so you can then design the plumbing. For a saltwater tank you want the water to drain into the overflow boxes(or drain system you have on your tank), drain into a sump (just another tank) and be pumped back up into the tank. Sumps are just another tank that have compartments to place different pieces of equipment. The sump hides all the equipment you will use as well, cycles your water, and adds more gallons to your system. The bigger your system, the easier it is to keep it stable.

I have to say at this point I did not know how to proceed on building a sump. This is where I advise go talk to people in the hobby. I went to my local fish store, Fintastic in Cary, NC and they were a huge help. In fact they built my sump for me. We chose a 55 gallon tank with a 3 compartment design. This is what the design and final sump looks like:

There is a lot of stuff in the sump. I will go through all of the equipment in post Part 2. As for the sump itself, the guys at Fintastic did a great job. If you want you can build a sump yourself or even buy one already made. When I was pricing sumps, it is much cheaper to build one yourself as opposed to buying one The only real work you need to do is add baffles to make the chambers. These baffles are just glass or Plexiglas that you will need to cut and glue in place. In my case I have three chambers. The baffles are placed in groups of three to keep bubbles from forming as the water moves from left to right through the sump and eventually pumped back up to the main tank.

There are a couple of things to think about when building a sump. The first is make sure it will fit the equipment you will place in the sump. The other thing to remember when choosing a sump is to chose one that will not overfill in the case of a power outage. When everything is set up and power is running, water is going to drain from the main tank, go through the sump and be pumped back up to the main tank. When the power goes out, the return pump stops working so water drains to a certain level in the main tank, but is not pumped back up. This means your sump will collect more water than normal so just make sure it can hold that extra water. When I lose power, my 55 gallon sump fills about halfway up.

3. PLUMBING - DRAIN LINES

We now have a tank and a sump and so the next thing to do is plumb your tank so you connect the two. First decide where you are going to locate your sump underneath the stand. This will help you decide where any pipes you run will need to go. In my case I put the sump all the way to the left side underneath my stand.

In my case I have two pre-drilled holes in each corner of my tank with an overflow. The first plumbing adventure is to take piping from each hole down to the very left side of my sump. The first chamber of my sump is where I will have water draining from the main tank.

This is where you need to make a a big choice. You can use flexible tubing or you can hard plumb with PVC pipe or you can use a mixture of both. I chose the latter to mostly use PVC pipe with some flex tubing.

No matter which type of piping you choose, you need to get bulkheads to be able to connect your piping to the aquarium while keeping any water from leaking out of the holes.

A bulkhead looks like this:

There are also strainers you can add to the water side of your bulkhead if you wish. This is how you attach a bulkhead to your tank. Put the threaded portion through the hole. The rubber gasket should be on the water side. Screw the nut on the outside of the tank hand tight and then screw it another quarter turn with pliers. DO NOT OVER TIGHTEN!!

After the bulkheads are in you can start running your drain pipes. I used 1" PVC pipe to go from my bulkheads to my sump. Through this process I made a couple mistakes and also did a few things that were serendipitous that I really recommend.

a. Bulkheads and plumbing- Pay attention. The very first mistake I made was I installed the threaded part of the bulkhead through the tank hole and was going to attach the first piece of PVC pipe. I cut my pipe, glued it and added an elbow. After gluing everything I realized i had not put the nut on the bulkhead and the nut would not fit over the elbow. CRAP! I had to cut the pipe and start all over. Of course the bulkhead was now ruined.

b. Bulkheads - don't go cheap. After the idiotic mistake above I needed to use a new bulkhead. The guy I bought tank from had given me two bulkheads. I had bought two new ones because the ones the guy gave me felt a little bit lighter and were older. But since I wanted to get my plumbing done I used one of them. Fast forward weeks later after I filled my tank with water and I came home to water leaking in a steady drip at my bulkhead. I tried everything to fix it and could not. I had to make another cut just like in the picture above, buy a new bulkhead and redo that piece of piping. Come to find out I had a small crack in the bulkhead flange that was causing the leak. I knew the bulkhead felt a little cheap and used it anyway. I paid for that mistake.

c. Use Unions!! - If you go the PVC route use unions. I had decided I would use unions so I could break the pipe down into smaller pieces if I ever needed to relocate my tank. In reality when i had the 2 mishaps above the unions made it much easier to just replace piping up to the union and not replace everything! Thanks goodness I had unions or fixing my mistakes would have been more time consuming and costly.

d. Ball valves - I have two overflows, two bulkheads, and so I have two sets of piping for draining water to the sump. On each set of pipes I installed one ball valve. I don't know why I did this other than I had read one forum post that someone did it and thought it looked nice. Once my tank was up and going, the water draining into one of my bulkheads was making a terrible gurgling noise. It was loud enough to drown out the TV when it was on. I started reading about fixes and the first thing I saw was to use a ball valve to help eliminate the noise. By restricting the water flow in your pipe to just what is needed to get the water through you eliminate the air going through the pipes. The air is what is causing the noise. I turned the ball valve just a little and the noise stopped! Ball valves to the rescue!

e. PVC pipe ends in flexible tubing. - I am glad I did this. I have water going from the tank, through the pipes and into the sump. I attached a small piece of flexible tubing the PVC pipe at the end which makes it much easier to divert water where I need to in my sump. I glued a PVC tube adapter to the end of the PVC, attached a piece of flexible hose and used a clamp to make sure it is attached well.

Drain Line Run #1: This was the farthest run from the bulkhead to the sump. You can see I have 2 unions and ball valve.

Drain Line Run# 2: This was just a straight shot from the bulkhead to the sump right underneath.

Drain Line Run # 2: I used one Union and the ball valve is right at the bottom. You can also see the flex tubing connected at the end of Run #1. Run#2 is set up the same way (the flex tubing is not visible in the picture).

4. PLUMBING - RETURN LINE

We are now plumbed for water to drain, but we also need to be able to get water back up to the main tank. The last chamber of my tank will house the return pump. i again went the flex tubing and PVC combination route.

I have a piece of flex tube running from the pump and then connected to PVC. For the reture line run I used 3/4" PVC pipe instead of 1". I used flexible tubing first on the recommendation that PVC attached directly to the reture pump can cause more vibration noise than if you use flex. The flex tubing attached to the return pump also lets me move the return pump around in the sump a little move and gives flexibility if the return pump breaks and needs repair. And that is a story I will share in a future post.

My design was return pump -> section of flex tubing -> PVC pipe. As the PVC pipe comes up to the top of the aquairum I used a 90 degree elbow and connected loc-line to split it to Y and go back into the tank.

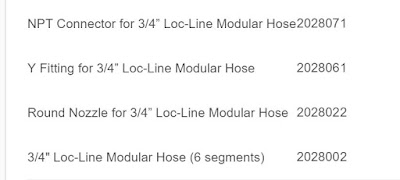

I bought the loc-line supplies at Bulk reef supply.

Just use the Y fitting to connect the loc-line hose. These loc-lines are easy to bend and move around.

The water return: Flex tubing to the PVC with a union. The union will help if I even need to take the system down or make repairs. The loc-line is at the top and will take the water back in the tank.

The entire system after all plumbing and before water has been added.

I will go over all the equipment you need to get your tank running in Part 2.

No comments:

Post a Comment